Operation Breakdown for Manufacturing a Denim Shirt

Introduction

Creating a high-quality denim shirt involves a series of meticulous operations, from the initial design phase to the final packaging. Each step in this process is crucial to ensure the shirt is not only stylish but also durable and comfortable. This operation breakdown provides a detailed overview of the key stages involved in manufacturing a denim shirt, highlighting the importance of each task and the attention to detail required to produce a garment that meets industry standards. Whether you’re a designer, a manufacturer, or simply curious about the production process, this guide offers valuable insights into the art and science of making a denim shirt.

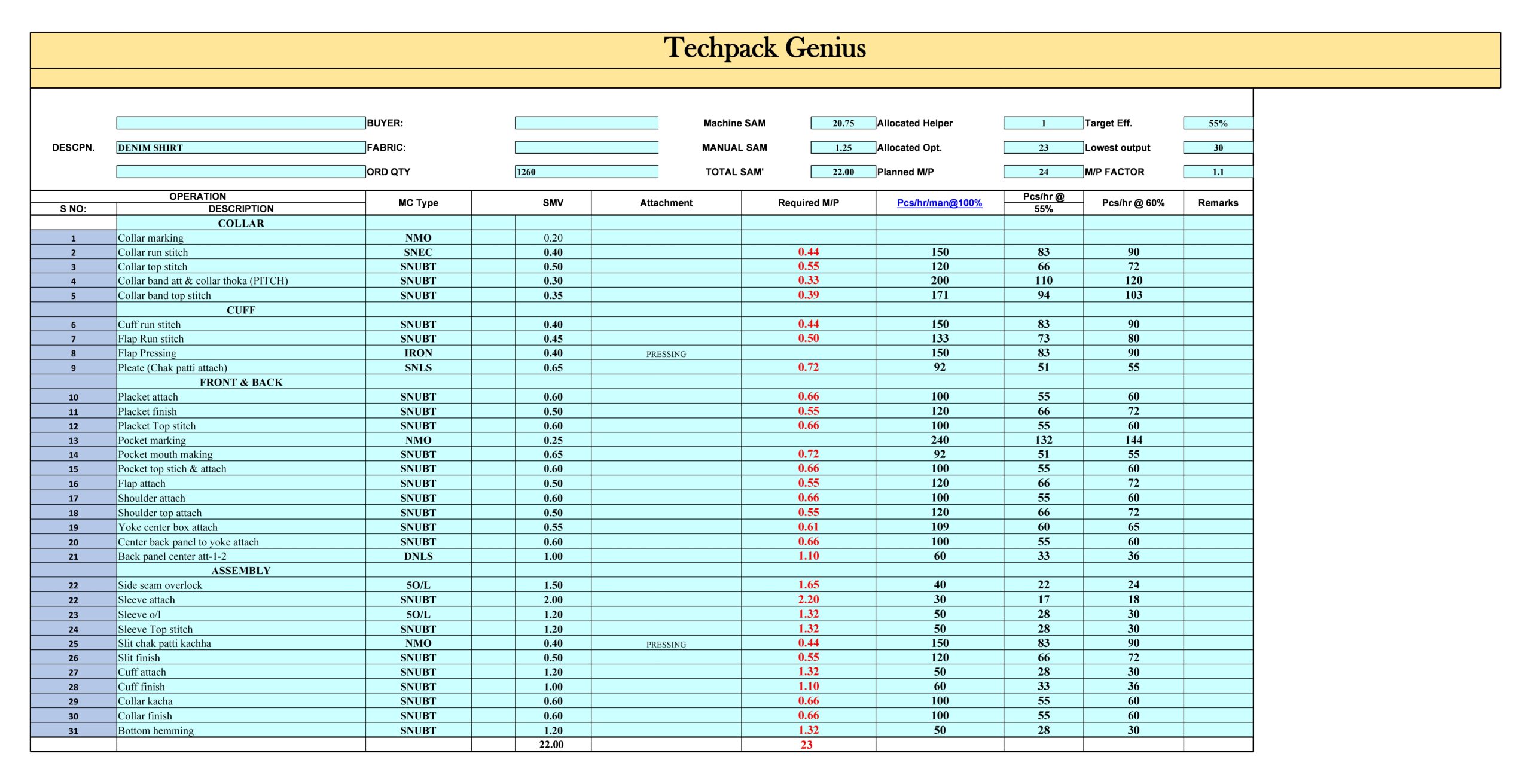

Operation Breakdown

Denim Shirt Operation Breakdown

1. Design and Pattern Making

– Conceptualization: Create the design concept for the denim shirt, including style, fit, and features.

– Pattern Development: Develop patterns for each part of the shirt (e.g., front panels, back panel, sleeves, collar, cuffs, pockets).

2. Fabric Selection and Cutting

– Fabric Selection: Choose high-quality denim fabric with the desired weight and texture.

– Marker Making: Create a marker layout to optimize fabric usage and reduce waste.

– Fabric Cutting: Cut the fabric pieces according to the marker layout using cutting machines or hand tools.

3. Sewing Operations

– Stitching Front Panels: Sew the front panels together, including the placket (button panel) and any decorative stitching.

– Attaching Pockets: Attach and stitch the pockets onto the front panels.

– Joining Shoulder Seams: Sew the shoulder seams to join the front and back panels.

– Attaching Sleeves: Sew the sleeves onto the armholes of the shirt body.

– Sewing Side Seams: Stitch the side seams to complete the shirt body.

– Collar Assembly: Sew the collar pieces together and attach the collar to the neckline.

– Cuff Assembly: Sew the cuff pieces and attach them to the sleeve ends.

– Hemming: Hem the bottom edge of the shirt and the sleeve ends for a clean finish.

4. Finishing Operations

– Buttonholes and Buttons: Create buttonholes and attach buttons on the front placket, cuffs, and collar.

– Labeling: Attach brand labels, care labels, and size tags.

– Trimming: Trim any loose threads and inspect the shirt for any defects.

– Pressing: Press the shirt to remove wrinkles and ensure a crisp appearance.

5. Quality Control

– Inspection: Conduct a thorough inspection to check for any defects or inconsistencies.

– **Testing:** Perform various tests (e.g., seam strength, colorfastness) to ensure the shirt meets quality standards.

6. Packaging and Shipping

– Folding and Packing: Fold the shirt neatly and pack it into protective packaging.

– Labeling and Shipping: Label the packages with relevant information and ship them to retailers or customers.

This breakdown covers the key operations involved in the production of a denim shirt. Let me know if you need more details or have any specific requirements!