The Importance of TechPack in Garment Manufacturing | Key to Efficient Production

In the fast-paced world of garment manufacturing, efficiency, precision, and communication are key to ensuring successful production runs. Whether you’re a fashion designer, a brand, or a manufacturer, a well-constructed techpack serves as the backbone of the garment creation process. It is a vital document that ensures all stakeholders are on the same page, from design conception to finished product. But what exactly is a techpack, and why is it so crucial in the garment manufacturing process? Let’s delve deeper.

What Is a Techpack? | Techpack in Garment Manufacturing

A techpack, short for technical package, is a detailed document that contains all the essential information necessary to produce a garment. It is essentially the blueprint that communicates the design, construction, and production details to the manufacturer. Think of it as a roadmap for the entire garment creation process, outlining everything from the fabric type to the size specifications, construction methods, and labels.

The Techpack in Garment Manufacturing includes a range of important components, such as:

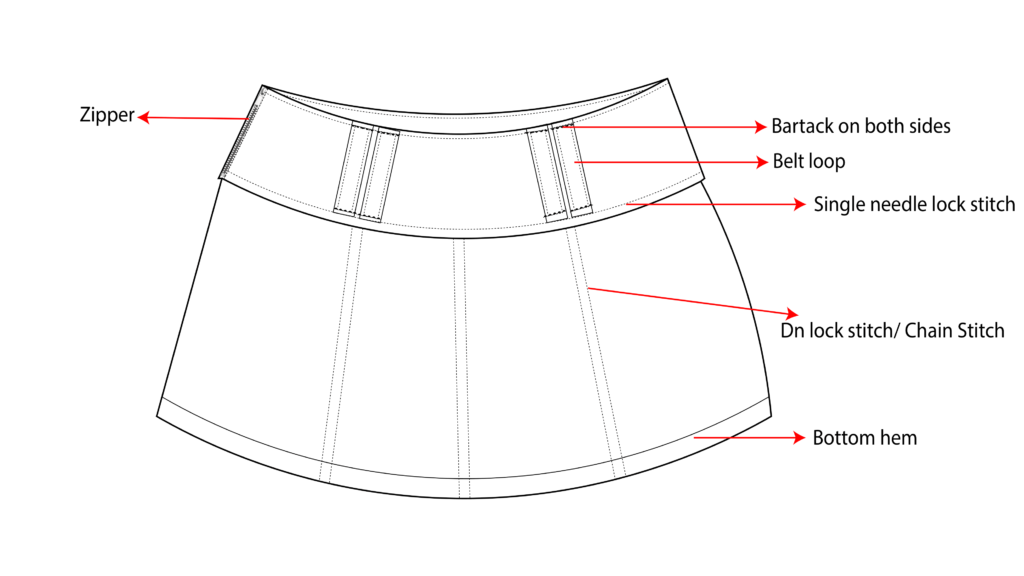

- Design sketches: Visual representations of the garment, including technical drawings that show how the garment should look from various angles.

- Material specifications: A detailed list of the fabrics, trims, and other materials required for the garment, including color codes and texture details.

- Size charts: Measurements for various sizes, ensuring that the garment fits correctly across different body types.

- Construction details: Instructions on how the garment should be sewn, including seam types, stitching details, and finishes.

- Labeling and care instructions: Information on the labels to be used in the garment and washing or care instructions.

- Production timeline: A schedule outlining the production process, from prototype creation to delivery.

- Costing information: A breakdown of the cost per unit, including material costs, labor costs, and overheads.

Having all of this information in one place ensures that every step of the garment manufacturing process is meticulously planned and executed, with no room for miscommunication or errors.

Importance Techpack in Garment Manufacturing

Now that we understand what a techpack entails, let’s explore why it is so essential in the garment manufacturing industry.

1. Techpack in Garment Manufacturing Ensures Consistency Across Productions

In the garment industry, maintaining consistency across multiple production runs is critical. A techpack provides manufacturers with the exact specifications for each garment, ensuring that the end product remains the same regardless of the production batch. Without a detailed techpack, there is a higher risk of discrepancies between the prototype and the final product, resulting in poor quality or a product that doesn’t meet the design specifications.

For example, if a designer creates a beautiful jacket with intricate stitching, the techpack will ensure that every detail, from the type of stitching to the thread color, is followed precisely during production. This consistency builds brand reputation and ensures customer satisfaction.

2. Techpack in Garment Manufacturing Improves Communication Between Designers and Manufacturers

One of the most common sources of problems in garment manufacturing is poor communication between the designer and the manufacturer. A techpack eliminates this issue by providing a clear and comprehensive guide that all parties can refer to. Designers can express their vision, and manufacturers can refer to the technical details, reducing the chance of misunderstandings or mistakes.

This streamlined communication also reduces the need for constant back-and-forth between the design and production teams. It enables manufacturers to work independently with all the information they need, without having to rely on verbal instructions or unclear guidelines.

3. Techpack in Garment Manufacturing Speeds Up the Production Process

Time is money, especially in the competitive garment manufacturing industry. When manufacturers have a detailed techpack, they can quickly start production without wasting time on clarifying ambiguities or making guesswork decisions. The inclusion of all essential details, such as materials, sizes, and construction methods, enables them to source materials and begin the manufacturing process promptly.

Additionally, techpack help speed up the sample approval process. With a techpack in hand, manufacturers can create accurate samples that meet the designer’s expectations, and designers can approve or make adjustments much faster, minimizing delays.

4. Techpack in Garment Manufacturing Reduces Errors and Costly Mistakes

In garment manufacturing, even small errors can lead to significant financial losses. Whether it’s choosing the wrong fabric, misinterpreting sizing, or using incorrect stitching techniques, errors can result in defective products that have to be scrapped, causing both delays and additional costs.

A well-constructed techpack acts as a safeguard against these mistakes. By providing precise instructions for every step of the production process, a techpack ensures that manufacturers can follow the design as intended, minimizing errors and preventing costly mistakes.

5. Techpack in Garment Manufacturing Streamlines the Sourcing of Materials

When it comes to sourcing materials for garment production, having a techpack makes the process much more efficient. The techpack contains detailed information about the fabrics, trims, and other components required for the garment, allowing manufacturers to source everything they need in a more organized manner.

For designers and brands, having a clear outline of materials in the techpack also helps them better understand the cost implications of their designs. If certain fabrics or components are expensive or hard to source, they can make informed decisions and adjustments before production begins, avoiding costly changes down the line.

6. Techpack in Garment Manufacturing Facilitates Quality Control

Quality control is another crucial aspect of garment manufacturing. A techpack acts as a reference point during the production process, helping manufacturers ensure that the garment is being produced to the required standards. Inspectors can refer to the techpack during each stage of production to confirm that the garment meets the specifications in terms of fabric quality, stitching, sizing, and finishing.

Techpacks also make it easier to identify and correct quality issues early on. If a garment doesn’t meet the required standards during production, the issue can be traced back to the techpack, helping manufacturers identify the specific problem and resolve it promptly.

7. Techpack in Garment Manufacturing Supports Cost Management and Pricing

Creating a garment involves multiple costs, including materials, labor, and overhead. A techpack includes a breakdown of these costs, which helps manufacturers and brands manage their budgets more effectively. By understanding the cost per unit, they can make better decisions about pricing and ensure that the production process remains cost-effective.

This breakdown also allows brands to understand where they can optimize costs, whether by choosing different materials, adjusting manufacturing techniques, or finding ways to streamline the production process.

Conclusion

Techpack in Garment Manufacturing process, a techpack is more than just a document – it is a vital tool that drives efficiency, ensures consistency, and promotes effective communication. Whether you are a designer, brand, or manufacturer, having a detailed techpack can streamline production, reduce errors, and save both time and money.

As the fashion industry continues to evolve and grow, the importance of techpacks will only increase. They are essential for meeting the demands of modern consumers, who expect high-quality products delivered on time. For any business looking to succeed in garment manufacturing, investing the time and resources to create a thorough and accurate techpack is a decision that will pay off in the long run.