How to Create a Perfect Tech Pack: Step-by-Step Process

Creating a perfect tech pack is an essential skill for any fashion designer, manufacturer, or apparel brand. A tech pack serves as a blueprint for your garment designs, ensuring that every detail is captured and communicated to manufacturers so that the finished product matches your creative vision. Whether you are new to tech packs or an experienced designer, having a clear and organized tech pack is vital for streamlining the production process and ensuring consistent results.

In this comprehensive guide, we will walk you through the step-by-step process of creating the perfect tech pack, from conceptualization to the final product. You’ll learn the purpose of each section, what information to include, and how to organize it effectively.

What is a Tech Pack?

A tech pack (short for technical package) is a document that contains all the detailed information needed to bring a garment design from concept to production. It acts as a communication tool between designers and manufacturers, ensuring that both parties are aligned on every aspect of the design. A well-crafted tech pack reduces the risk of miscommunication, production errors, and costly delays.

Tech packs typically include the following:

- Design sketches

- Material specifications

- Construction details

- Size and fit information

- Costing and pricing details

- Manufacturing instructions

By creating a clear and comprehensive tech pack, you provide your manufacturer with everything they need to produce your garments as envisioned.

Why Tech Packs Are Important

Before diving into how to create a perfect tech pack, let’s take a moment to understand why they are crucial:

1. Clear Communication

Tech packs ensure that your manufacturer knows exactly what to do. They contain all the specifications for the design, materials, fit, and other details. This eliminates the need for constant back-and-forth communication and prevents misunderstandings.

2. Reduces Errors

A tech pack clearly outlines every detail of your design, minimizing the chance of errors during production. Without a tech pack, manufacturers might make assumptions or misinterpret your intentions, leading to faulty garments or delays.

3. Time and Cost Efficiency

With all the necessary information in one place, tech packs help manufacturers quickly understand your design. This leads to faster sampling, production, and fewer revisions, ultimately saving you both time and money.

4. Scalability

If you need to scale up production, having detailed tech packs allows you to do so without compromising on quality. You can easily share your tech packs with multiple manufacturers or suppliers, ensuring that production runs smoothly.

Step-by-Step Process of Creating a Tech Pack

Now that we understand the importance of tech packs, let’s dive into the process of creating one. Below are the key steps involved in creating the perfect tech pack.

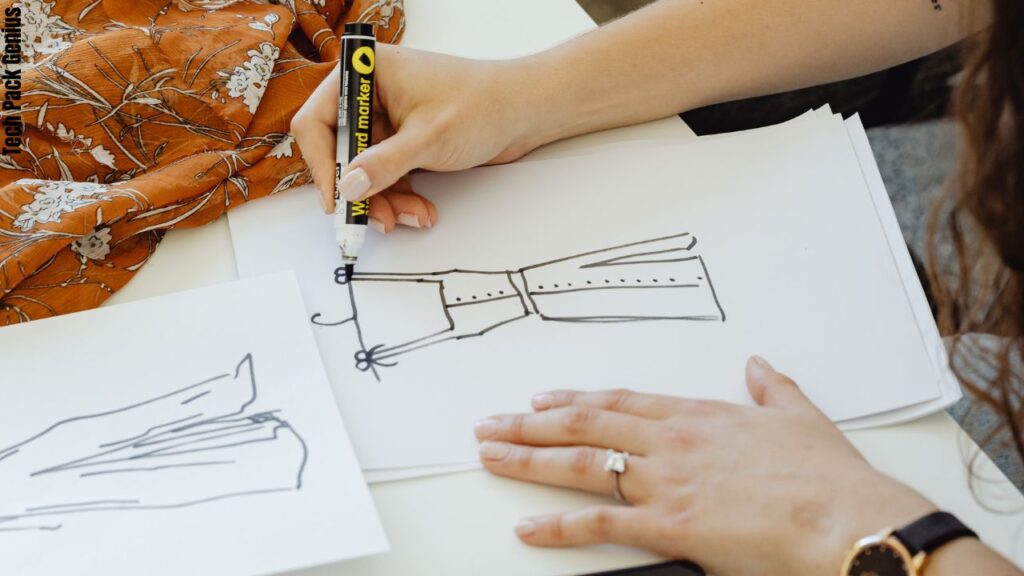

Step 1: Start with a Design Sketch

A design sketch is the first visual representation of your garment. It helps to communicate your ideas clearly and accurately. Whether you create your designs by hand or use digital design tools like Adobe Illustrator, make sure your sketch captures the overall concept of the garment.

Tips for a Perfect Design Sketch:

- Be detailed: Include front and back views of the garment, along with any specific design features like seams, pleats, or pockets.

- Add dimensions: Include measurements to show proportions, as this will help manufacturers understand how the garment should fit.

- Indicate key design elements: Mark where trims, labels, zippers, or buttons will be placed. This gives manufacturers precise instructions.

Step 2: Create Technical Flats

While design sketches offer a creative perspective, technical flats are the more detailed, technical representation of the garment. These two-dimensional drawings show the garment from multiple angles and illustrate how the design should be constructed.

What to Include in Your Technical Flats:

- Front and back views of the garment.

- Construction details: Show stitching, seam types, and other technical elements.

- Measurement points: Label where key measurements like waist, bust, hips, and inseams should be taken.

- Trims and labels: Indicate the placement of labels, buttons, zippers, and other accessories.

Tools for Creating Technical Flats:

- Adobe Illustrator: The most popular software for creating technical flats.

- CLO 3D: A 3D garment design software that can also generate technical flats.

- CorelDRAW: A vector-based design tool used by some fashion designers.

Step 3: Define Fabric and Materials

One of the most crucial sections of a tech pack is the fabric and material specifications. This section provides detailed information about the fabrics, trims, and materials used in the garment. The quality and type of material you choose can greatly affect the final product, so it’s important to be as detailed as possible.

Information to Include:

- Fabric type: Specify whether it’s cotton, polyester, silk, wool, etc.

- Weight: How heavy or light is the fabric? This affects the garment’s drape and comfort.

- Color codes: Use Pantone color codes to ensure the manufacturer matches the colors exactly.

- Composition: Describe the fabric blend (e.g., 80% cotton, 20% polyester).

- Supplier details: Include information about your fabric suppliers, especially if you have specific sourcing requirements.

Step 4: Size Specifications and Grading

Sizing is one of the most critical aspects of a garment tech pack. Your tech pack should include size specifications for each size you plan to produce (e.g., S, M, L, XL). This ensures that the garment will fit correctly across different sizes.

What to Include in Size Specifications:

- Measurement chart: Provide measurements for various points of the garment, including bust, waist, hips, inseam, and sleeve length.

- Grading: Grading is the process of creating different sizes based on a base size. For example, you may need to adjust the bust measurement by a certain amount for size large and extra-large. Make sure you include grading rules.

- Fit comments: Include any notes about the desired fit of the garment (e.g., slim fit, loose fit, oversized).

Step 5: Construction Details and Instructions

This section outlines the garment’s construction details. It includes instructions on how the garment should be assembled and stitched. This information helps the manufacturer understand the garment’s structure and ensures consistent quality.

Details to Include:

- Seam types: Indicate the type of seams to be used (e.g., French seams, overlocked seams).

- Stitch type: Specify the type of stitching (e.g., straight stitch, zigzag stitch).

- Construction process: Outline how the garment should be put together, including how pieces should be joined and finished.

- Finishing techniques: Provide instructions for any finishing treatments such as hemming, pressing, or adding labels.

Step 6: Bill of Materials (BOM)

The Bill of Materials (BOM) is a comprehensive list of all the materials used in your garment. It includes fabrics, trims, labels, and other components. The BOM ensures that all materials are accounted for and ordered correctly.

What to Include in Your BOM:

- Fabric: Type, weight, color, and supplier information.

- Trims: Buttons, zippers, snaps, and other fasteners.

- Labels: Brand labels, care labels, size labels, etc.

- Packaging: Information on packaging materials and instructions for packaging.

Step 7: Costing and Pricing Details

Understanding the cost of production is essential for pricing your garment correctly. In your tech pack, you should provide detailed costing for each component of the garment. This will help you determine the price per unit and ensure that your manufacturing process is financially viable.

What to Include:

- Fabric costs: Breakdown of costs for each fabric type.

- Labor costs: The cost of stitching and assembling the garment.

- Trim costs: Prices for each trim or accessory used.

- Packaging costs: The cost of packaging materials.

- Manufacturing overhead: Any additional costs associated with the production process.

Step 8: Finalize the Tech Pack

After you’ve compiled all the details, review your tech pack carefully to ensure that all information is accurate and complete. Double-check measurements, materials, and construction details. It’s always a good idea to have a colleague or an expert review it as well to catch any errors or inconsistencies.

Conclusion

Creating a perfect tech pack requires attention to detail, organization, and clear communication. By following this step-by-step process, you can ensure that your designs are executed exactly as you envision. Whether you are a new designer or an established brand, mastering the art of tech pack creation will make your production process smoother, faster, and more efficient.

Remember, a tech pack is not just a document—it’s your garment’s blueprint for success. Take the time to create a comprehensive, well-organized tech pack, and you’ll set yourself up for a seamless transition from design to production.

Actionable Tips:

- Use digital tools: Consider using software like Adobe Illustrator, Techpacker, or CLO 3D to create your tech packs.

- Collaborate with your manufacturer: Always involve your manufacturer in the process early on to ensure they understand your design and specifications.

- Invest in quality materials: The fabric and materials you choose will greatly impact the final product, so don’t cut corners in sourcing.

By following these guidelines, you’ll create tech packs that not only communicate your vision clearly but also set the foundation for high-quality garment production.